Features of Tungsten Carbide Wire Drawing Die

Features of Tungsten Carbide Wire Drawing Die

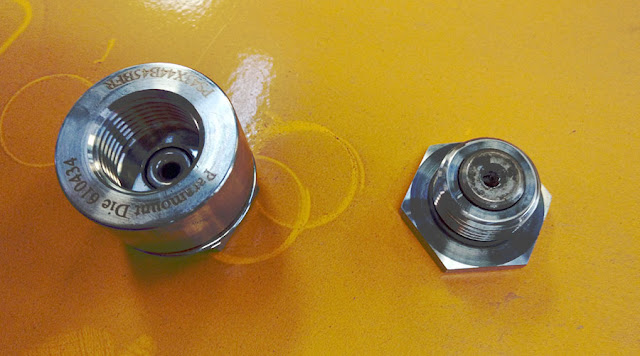

Although the materials of the drawing die can be different, among different drawing dies, the cemented carbide drawing dies to become the highlight. Today, tungsten carbide wire drawing dies to occupy an important position in the wire drawing industry. In this article, we will bring you the following characteristics of carbide wire drawing dies:

1. Strong power resistance

During the process of wire drawing and extrusion, the wire drawing die will be subject to large extrusion, bending stress, impact, and other messy loads. Therefore, the material selected to make the wire drawing die should have high power resistance and outstanding hardenability after heat treatment to ensure that the die can be uniformly hardened.

2. Excellent wear resistance

The wire drawing die should have high wear resistance to ensure normal service life and mass production of high-quality wire. Generally speaking, the hardness of tungsten carbide is directly proportional to the wear resistance under certain conditions. Therefore, the drawing die must have high hardness and wear resistance. In addition to hardness, the determining factors include thickness, composition, excess amount of matrix after heat treatment and the number, size, type, dispersion, and red hardness of carbides. The tungsten carbide content of tungsten carbide is more than 80%, and its wear resistance is several times higher than that of steel. Therefore, in order to prolong the service life of the wire drawing die, the material is mostly made of cemented carbide.

3. Sufficient heat resistance

For continuous production of wire, the temperature of tungsten carbide wire drawing dies may reach 200°C, which will reduce the strength and hardness of most materials, and tungsten carbide is a material with excellent thermal stability, which can maintain its properties at high temperatures.

4. Excellent processability

The wire drawing die must go through a long time to pull out the wire with high precision. Typically, casting, cutting, grinding, heat treating, or other finishing is required. Therefore, only materials with excellent processing properties can meet production needs. The excellent craftsmanship of cemented carbide molds will be the best choice.

These characteristics of the wire drawing die are reflected in its raw material, tungsten carbide, which has the characteristics of high hardness, wear resistance, good thermal stability, and excellent processing performance.

评论

发表评论