Introduction of Tungsten Carbide Wire Drawing Dies

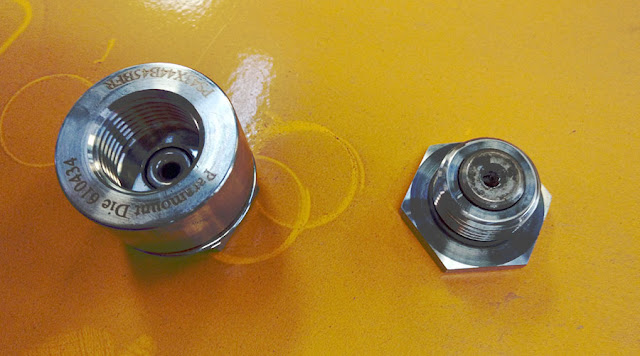

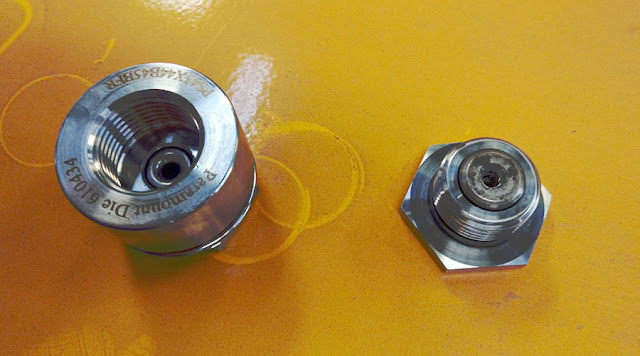

Introduction of Tungsten Carbide Wire Drawing Dies The carbide wire drawing dies to adopt high-quality tungsten carbide as the core, which has high hardness, good thermal conductivity, and low friction coefficient. Tungsten carbide wire drawing dies are simple to produce with corrosion-resistant, impact-resistant, and low cost, which has an outstanding feature of this product. It is suitable for ferrous metals, large-size wires, and occasions with poor wire drawing conditions. Wire drawing is the manufacturing process for reducing or changing the cross-section of the metal wire by using a series of stretched plates or molds. A Carbide wire drawing die is a kind of tungsten carbide dies with wide applications in various fields. YG6X: Suitable for the production of carbide dies withdrawing inner holes which are smaller xn--than 6-1de.00mm. YG6: Used for the non-ferrous metal round bar, which has drawing inner holes smaller than Φ20mm, and the drawing dies, which has inner holes smaller t